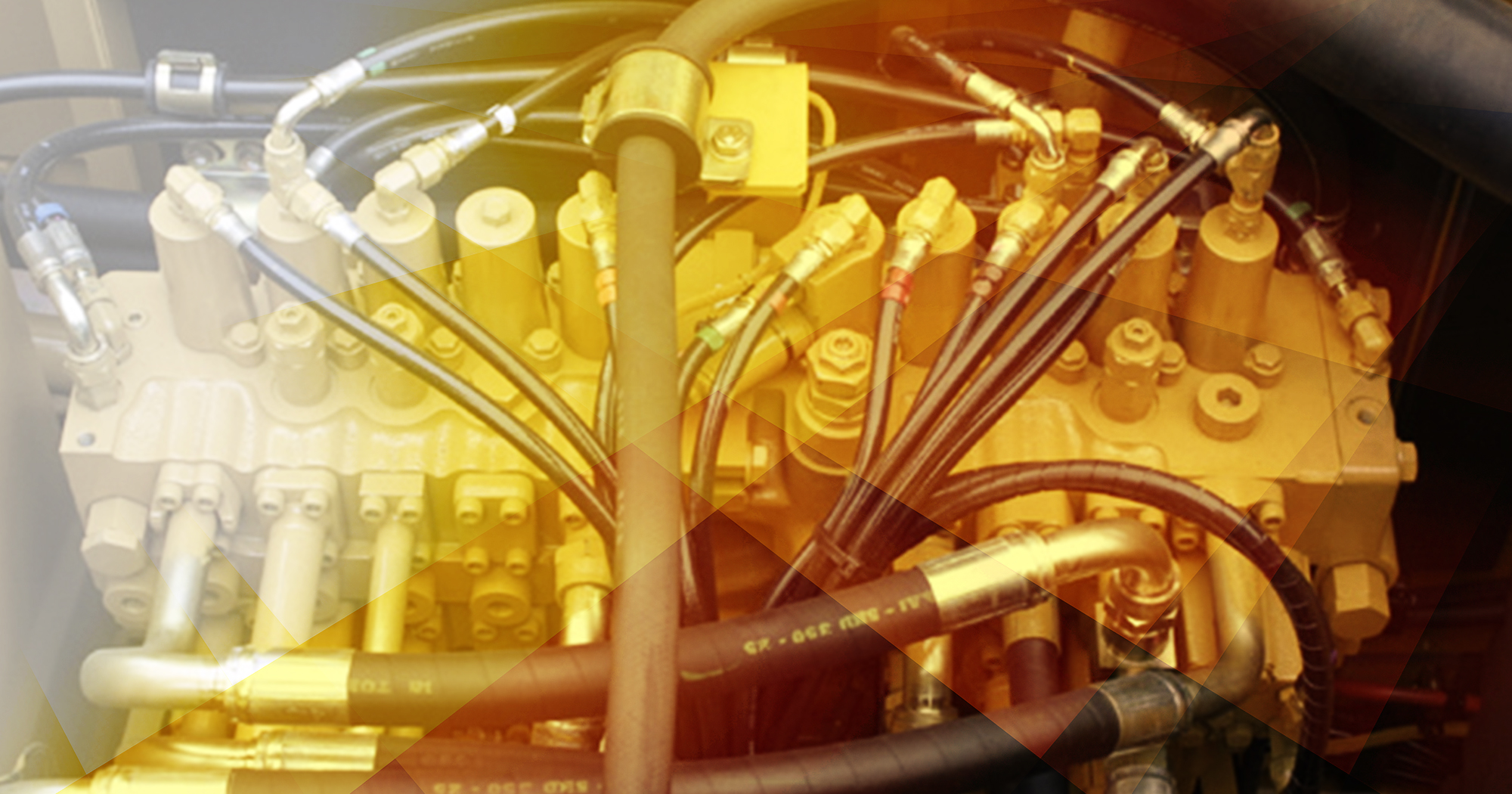

Hydraulics make the connection between machine power and job productivity. The Cat® hydraulics advantage starts with quality components that can deliver higher pressure thresholds than competitors. They’re built to meet the exacting specs of Cat equipment — from power and responsiveness to breakout force and speed. That’s important, because hydraulics are responsible for up to 20% of machine performance.

Because hoses and couplings carry the lifeblood of hydraulic equipment, Caterpillar supplies its own hoses, couplings and assembly kits. As for pumps and motors, they’re the heartbeat of any hydraulic system. That’s why Cat pumps and motors are uniquely designed for Cat machines, then 100% tested to deliver top performance in their intended equipment and applications.

Because hoses and couplings carry the lifeblood of hydraulic equipment, Caterpillar supplies its own hoses, couplings and assembly kits. As for pumps and motors, they’re the heartbeat of any hydraulic system. That’s why Cat pumps and motors are uniquely designed for Cat machines, then 100% tested to deliver top performance in their intended equipment and applications.

Hydraulic cylinders are complex and delicate, with tight tolerances needed to maintain the seal around the rod. Any leaks and machine performance can suffer. The key is to repair them before damage happens. That’s a vital job that your Cat dealer can help you with or take over for you so you can focus on your business.

Hydraulic cylinders are complex and delicate, with tight tolerances needed to maintain the seal around the rod. Any leaks and machine performance can suffer. The key is to repair them before damage happens. That’s a vital job that your Cat dealer can help you with or take over for you so you can focus on your business.

When it comes to operating heavy machines and equipment, hydraulic systems do the heavy lifting. These powerful pieces of equipment move impressive weights and provide the muscle behind tasks that are critical to the operations of so many companies. Given the sheer amount of work they do, hydraulic systems must be properly maintained. Failure to do so risks damage to vital components, efficiency losses and even worker injury.

When it comes to operating heavy machines and equipment, hydraulic systems do the heavy lifting. These powerful pieces of equipment move impressive weights and provide the muscle behind tasks that are critical to the operations of so many companies. Given the sheer amount of work they do, hydraulic systems must be properly maintained. Failure to do so risks damage to vital components, efficiency losses and even worker injury.

> Read the article: SOS Cat: Preventing equipment breakdown

How to maintain a hydraulic system?

How to maintain a hydraulic system?

It’s important to refer to manufacturers’ hydraulic system specifications to make sure

- all filters get changed on time,

- the correct fluids are used,

- the correct operating temperatures are maintained,

Here’s a basic checklist that’ll guide you in proper hydraulic system maintenance:

- Oil Maintenance

- Changing Filters Regularly

- Rod Conditions

- Seal Replacement

- Regular Hydraulic Lines Check-Up

- Inspect Fluid Levels

- Check Breather Caps, Fill Screens and Breather Filters

- Inspect Filter Indicators

- Visually Check All Pipes, Pipe Connections and System Hoses

- Check the System Temperature

- Visually Inspect Inside the Reservoir

- Listen to the Pumps

- Inspect a Sample of Hydraulic Fluid

- Perform Hydraulic Valve Maintenance

- Check the Electric Drive Motor

.png)